Showroom

A Level Indicator is crucial for measuring and displaying liquid or solid levels in containers, with 98% accuracy for precise process control. Featuring an analog display, it uses floats, sensors, and gauges for reliable measurements. Its robust construction supports efficient operation and safety across industries like chemical, pharmaceutical, and oil & gas.

A Rotameter measures flow rates of liquids and gases in industrial settings. It operates up to 50C with a manual power supply, using a tapered tube and float for direct flow readings. Key components include the float, tube, and scale markings. Essential in chemical processing, water treatment, and HVAC, it ensures accurate flow monitoring and reliable performance.

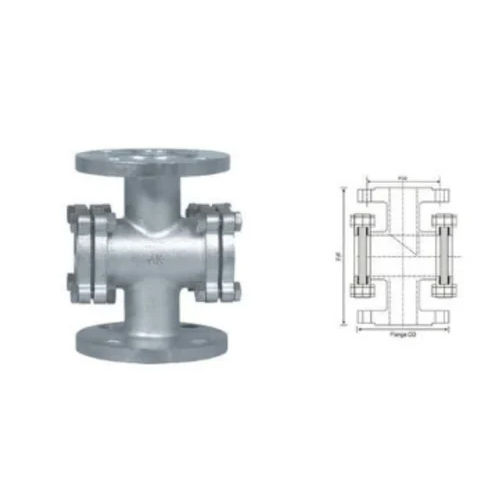

A sight flow indicator with a digital display is vital for monitoring fluid flow in industrial pipelines. It uses advanced technology to provide precise flow rate readings on a digital screen. Featuring a transparent viewing area and sensors, its made from durable materials like stainless steel, ensuring reliable real-time monitoring in sectors such as chemical processing and oil and gas.

A flame arrester is a critical safety device used in industrial settings to stop flames from spreading. Made from durable stainless steel, it resists corrosion and extreme temperatures. Typically 50 millimeters in diameter, it features a red color for visibility. With precise mesh or plate technology, it cools and traps flames, making it essential for petrochemical and manufacturing industries to prevent fire hazards in ventilation and exhaust systems.

Pneumatic valves are crucial for controlling gas flow in industrial settings. Made from durable stainless steel, they handle high pressure and come in sizes from 0.5 to 24 inches. Powered pneumatically, they feature advanced technology for precise control. Essential in industries like chemical processing and oil and gas, they enhance system performance and safety.

A magnetic level indicator measures liquid levels in tanks using a magnetic float and a clear visual display. Constructed from durable stainless steel, it features advanced engineering for precision. Key components include the float, magnetic coupler, and graduated indicator. Essential in industries like chemical processing and oil and gas, it ensures reliable monitoring.

Level switches are vital for monitoring and controlling liquid levels in industrial settings. Displacer switches use a buoyant displacer to activate a switch at preset levels, while top-mounted magnetic switches use a float to trigger level changes. Both types, made from durable materials like stainless steel, ensure accurate and reliable operation in industries such as chemical processing and oil and gas.

A pressure vacuum relief valve is essential for controlling pressure in industrial systems. Constructed from sturdy cast iron and available in sizes from 1" to 40", it features a spring-loaded diaphragm, valve seat, and actuator. It vents excess pressure and allows air intake to prevent vacuum conditions, ensuring stability in industries like chemical processing and oil and gas.

A manometer is essential for measuring pressure, featuring a 1/4 inch size and durable stainless steel construction. It offers an analog display with a range from 100-0-100 mm WC to 1000-0-1000 mm WC. Manual power ensures reliability, making it ideal for industries like chemical processing and HVAC.

Manual valves, including breather and pressure relief types, are crucial in industrial settings. Made from durable stainless steel and available in blue and silver, they are custom-sized for water applications and function well at standard temperatures. Advanced engineering ensures reliable performance with key components like a valve seat, actuator, and manual handle.

A pressure transmitter, used in industrial settings, monitors and controls critical pressure differentials. Constructed from steel and plastic, it operates at 220 volts and is often blue. Key components include a pressure sensor, signal transmitter, and processing unit. Its advanced technology ensures precise pressure measurements and reliable performance in diverse industries.

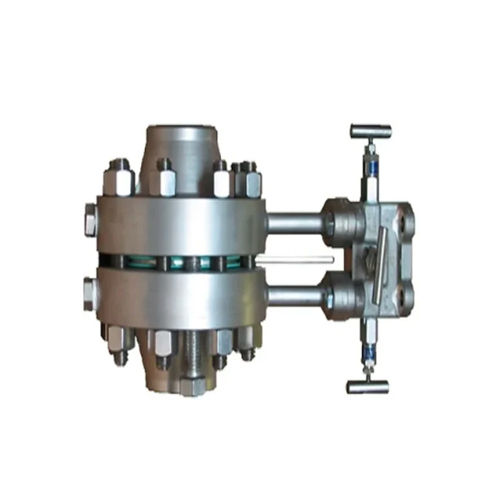

An orifice plate, made of stainless steel and 3/4 inch in size, is essential for flow measurement in chemical fertilizer pipes. Silver in color, it is used in oil and gas, chemical processing, water treatment, and HVAC systems. Its precise engineering ensures accurate flow control and reliable performance across industries.